Open-loop and Closed-loop Control by using Continuous Valves

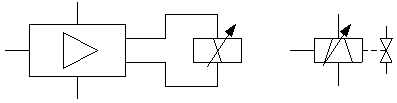

Among simple way valves with only discrete switching positions, FluidSIM also provides a number of continuous valves. These are particularly interesting because they may represent continuous intermediate positions. These components are addressed - in the same way as electrically operated way valves - by using a proportional amplifier or a valve solenoid. These are represented by specific symbols:

The individual proportional

valve solenoid is used with position controlled continuous valves

that integrate the controller and amplifier part in their

valve.

The individual proportional

valve solenoid is used with position controlled continuous valves

that integrate the controller and amplifier part in their

valve.

If you unintentionally link

a way valve with a proportional valve solenoid or vice versa a

proportional valve with a simple valve solenoid by using a label,

FluidSIM will show a warning.

If you unintentionally link

a way valve with a proportional valve solenoid or vice versa a

proportional valve with a simple valve solenoid by using a label,

FluidSIM will show a warning.

The following two sections will introduce you to the possibilities of open-loop control and closed-loop control with FluidSIM. The term “open-loop control” means here that an output variable changes depending on an input variable. In detail the voltage represents the input variable at the proportional valve solenoid or at the amplifier. Depending on the value (and on the direction) of the electrical current caused by the voltage (assisted by an amplifier), the valve piston of the proportional valve will more or less be deflected to one direction. This is the output variable. In the case of a constant pressure at the valve port you may therefore manage the flow. Instead, in the case of a constant flow, the pressure drop will change depending on the opening level that is defined by the valve position.We speak of “closed-loop control” when the output variable or a state variable influenced by this output variable itself serves as an input variable. In the course of this several output variables as well as pending state variables may well be combined with further input variables when a calculation rule is used. A classical example is represented by a position control that defines a particular position to be reached by a cylinder. In this case the valve will be electrically addressed in such a way that the cylinder travels. The position of the cylinder (in consequence of the travel depending on the valve position) will again be used as an input value while the deviation from the desired position of the cylinder is considered. Once the cylinder has reached its target position, the deviation is 0 and the valve returns to mid-position (closed position). Thus the cylinder stops. Should the cylinder, by inertia or because of outside malfunction or interference, pass the target position, the valve will switch to the opposite side and will reverse the direction of flow; the cylinder travels back. This already represents the simplest form of controlling, the so-called “P-control”.