Creating new Circuit Diagrams

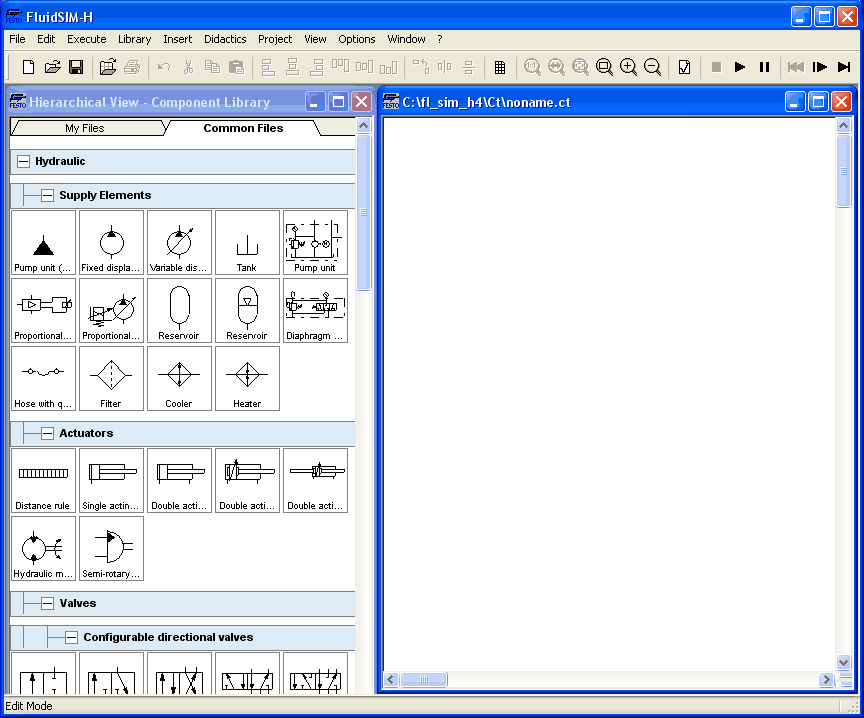

This section contains an introduction to creating and simulating circuit diagrams using FluidSIM.

Create an empty

drawing area by clicking on

Create an empty

drawing area by clicking on  or under

File- New to open a new

window:

or under

File- New to open a new

window:

Circuit diagrams can only be

created or altered in the Edit Mode. The Edit Mode is indicated

with the following mouse cursor

Circuit diagrams can only be

created or altered in the Edit Mode. The Edit Mode is indicated

with the following mouse cursor  .

.

Each and every newly opened drawing area automatically contains a name, with which it can be saved. This name is found in the title bar of the new window.

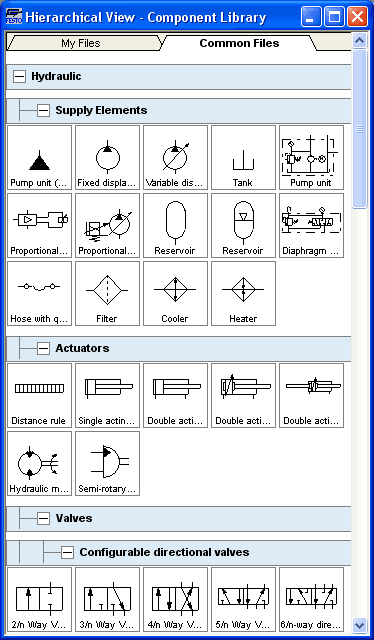

While in basic mode, you will see the available component groups in the hierarchical view of the component library. To list the components of a group, you may list off the group by clicking it. For a better overview you may also hide non-required elements and subgroups by once more clicking and hence closing the hierarchy. Component groups may often contain further subgroups that may also be listed off or closed.

To list off a group including all of its subgroups, you may hold the Shift-Key while clicking. This will reduce your efforts to list off each subgroup. You may similarly use the Shift-Key to close all subgroups of a superordinate group.

press the

Shift-Key, hold it and click “Hydraulic”.

press the

Shift-Key, hold it and click “Hydraulic”.

The entire group of hydraulic components will be listed off. Using the scrollbars, you may browse through the component library to the left and right or up and down.

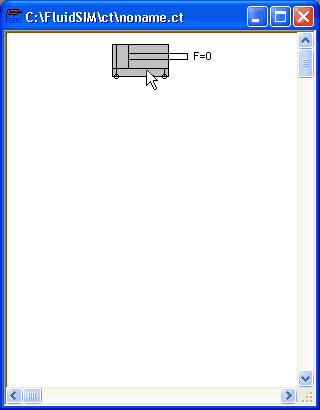

Using the mouse and “drag-and-drop” you may drag components from the component library to the drawing area:

Move the mouse

cursor to a component in the library, more specifically to the

cylinder.

Move the mouse

cursor to a component in the library, more specifically to the

cylinder.

Press the left

mouse button. While continuing to hold down the button, move the

cursor.

Press the left

mouse button. While continuing to hold down the button, move the

cursor.

The cylinder is

then highlighted (selected) and the mouse cursor changes

to a four way directional cross  . The component's outline

moves with the mouse cursor.

. The component's outline

moves with the mouse cursor.

Move the cursor

to the drawing area and release the button on the mouse. This

action places the cylinder in the drawing area:

Move the cursor

to the drawing area and release the button on the mouse. This

action places the cylinder in the drawing area:

In this way it is possible to “drag” each component from the component library and place it in the desired position in the drawing area. In the same way it is possible to rearrange components already in the drawing area.

Drag the

cylinder to the bottom right hand corner.

Drag the

cylinder to the bottom right hand corner.

In order to simplify the

creation of circuit diagrams, the components automatically snap

to grid in the drawing area.

In order to simplify the

creation of circuit diagrams, the components automatically snap

to grid in the drawing area.

Try to move the

cylinder onto a non-permissible area, for example outside the

window.

Try to move the

cylinder onto a non-permissible area, for example outside the

window.

Outside a

permissible area the mouse cursor changes to the prohibited

sign  ; the component cannot be

dropped.

; the component cannot be

dropped.

Drag a second

cylinder onto the drawing area and notice that the second

cylinder is now highlighted.

Drag a second

cylinder onto the drawing area and notice that the second

cylinder is now highlighted.

Highlight, say,

select the first cylinder by clicking on it.

Highlight, say,

select the first cylinder by clicking on it.

Delete the

cylinder by clicking on

Delete the

cylinder by clicking on  (cut) or under

Edit- Delete or by pressing the

Del key.

(cut) or under

Edit- Delete or by pressing the

Del key.

The commands in the

Edit

menu correspond

only to the selected components.

The commands in the

Edit

menu correspond

only to the selected components.

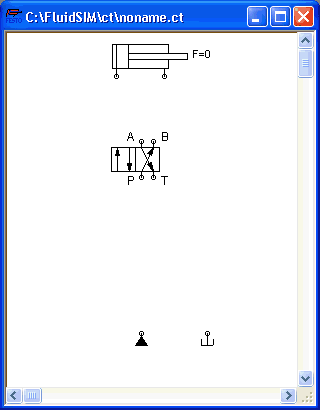

Drag onto the

drawing area a configurable 4/n-way valve, a pump unit, and a

tank.

Drag onto the

drawing area a configurable 4/n-way valve, a pump unit, and a

tank.

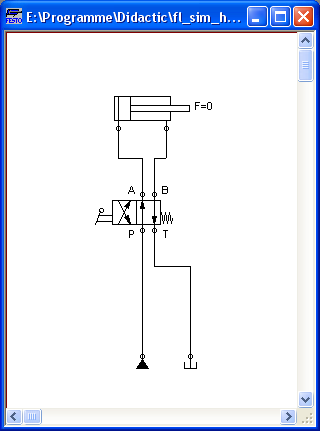

Arrange the

components in the following manner:

Arrange the

components in the following manner:

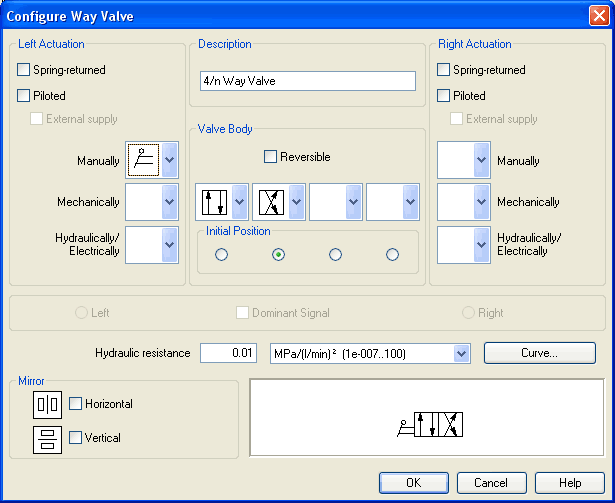

Double click the valve to assign an operation mode to it. A dialog box appears:

- Left/Right ActuationFor both sides the actuation modes of the valve can be defined individually; it can be one or more of the categories “Manually”, “Mechanically”, or “Hydraulically/Electrically”. An operation mode is set by clicking on the down-arrow at the right-hand side of the list and selecting a symbol. If for a category no operation mode is desired, simply choose the blank symbol from the list. Moreover, for each side of the valve the attributes “Spring-returned” and “Piloted” can be set.

- Description

Enter here a name for the valve. This name is used in the state diagram and in the parts list. - Valve

Body

A configurable valve has at most four positions. For each of the positions a valve body element can be chosen individually. Such an element is set by clicking on the down-arrow at the right-hand side of the list and selecting a symbol. If for a position no element is desired, simply choose the blank symbol from the list. The valve may be marked “Reversible” to indicate that there is no particular direction of flow. - Initial

Position

This button defines the valve's initial position (sometimes also called normal position or neutral position), which is the position without having any operation applied to the valve. Note that this setting is only exploited if it physically does not contradict a spring-returned setting, possibly defined above. - Dominant

Signal

A “Dominant signal” on the left or right-hand side defines the overriding signal, in case the valve is addressed from both sides simultaneously. - Hydraulic

Resistance

This is where you define the hydraulic resistance of the valve.

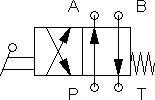

Choose from the left-hand

side in the topmost list a manual operation with snap in, and

select the “Spring-returned” option in the right field. Close the

dialog box via OK.

Choose from the left-hand

side in the topmost list a manual operation with snap in, and

select the “Spring-returned” option in the right field. Close the

dialog box via OK.

Now the valve should look as follows:

Move the mouse

cursor over the left cylinder connection .

Move the mouse

cursor over the left cylinder connection .

In Edit Mode,

the mouse cursor changes to a cross-wires pointer

, when it is above a

component connection .

, when it is above a

component connection .

Press the left

mouse button while the mouse cursor is above the cylinder

connection. Move the mouse cursor and notice how the cross-wires

pointer gains arrows

Press the left

mouse button while the mouse cursor is above the cylinder

connection. Move the mouse cursor and notice how the cross-wires

pointer gains arrows  .

.

Keep pressing

the mouse button, and move the cross-wires pointer

Keep pressing

the mouse button, and move the cross-wires pointer

to the upper left

valve connection. Notice how the arrows on the cross-wires

pointer turn inward

to the upper left

valve connection. Notice how the arrows on the cross-wires

pointer turn inward  .

.

Release the

mouse button.

Release the

mouse button.

Immediately a line appears between the two chosen connections:

FluidSIM

automatically draws a line between the two chosen connections.

The mouse cursor changes to the prohibited sign

when it is not

possible to draw a line between two connections.

when it is not

possible to draw a line between two connections.

Move the mouse

cursor to a line.

Move the mouse

cursor to a line.

In the Edit

Mode, the mouse cursor changes to a line-selection symbol

, when it is positioned over

a line.

, when it is positioned over

a line.

Press the left

mouse button and move the line-selection symbol to the left.

Release the mouse button.

Press the left

mouse button and move the line-selection symbol to the left.

Release the mouse button.

Immediately, the line is redrawn:

In the Edit Mode the components and lines can be selected, moved, or deleted by clicking on Edit- Deleteor by pressing the Del key.

Connect the

remaining components.

Connect the

remaining components.

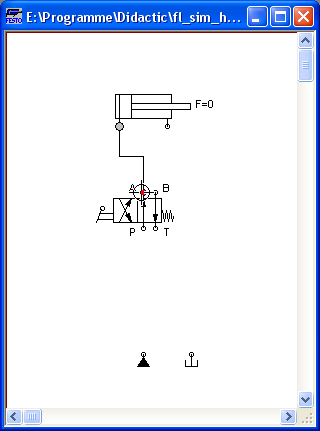

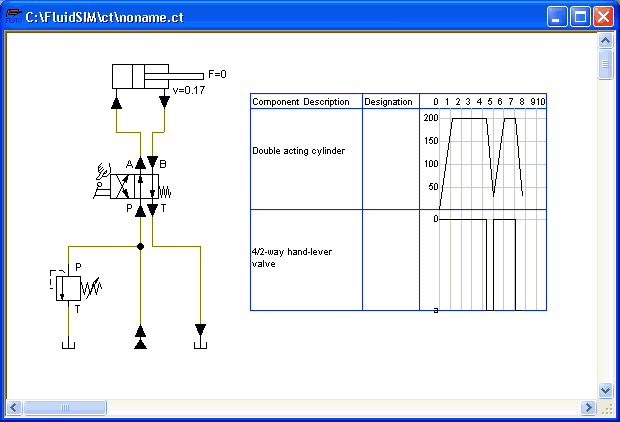

The circuit diagram should look somewhat like the following one:

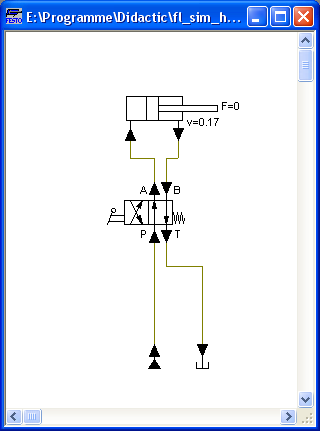

The circuit diagram has been completely drawn and connected. Attempt to simulate this circuit.

Start the

simulation by clicking on

Start the

simulation by clicking on  (or under

Execute- Start or with the F9

key).

(or under

Execute- Start or with the F9

key).

During simulation all pressures and flow rates are calculated, all lines are colored, and the cylinder's piston extends.

After the cylinder has been extended, the pressure in the cylinder supply line must inevitably increase. This situation is recognized by FluidSIM and the parameters are recalculated; the pressure downstream of the pump unit increases to the value, as defined by the pump unit safety guard.

In order to keep the value of the maximum pressure low, the pump unit must be equipped with a pressure relief valve.

Activate the

Edit Mode by clicking on

Activate the

Edit Mode by clicking on  (or under

Execute- Stop or with the F5

key).

(or under

Execute- Stop or with the F5

key).

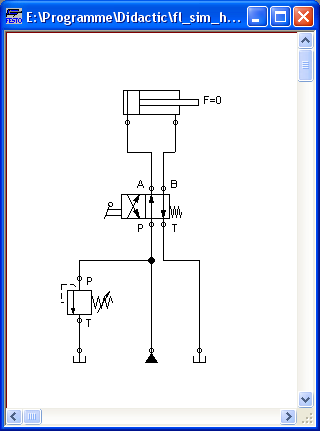

Drag a pressure

relief valve and a second tank into the window.

Drag a pressure

relief valve and a second tank into the window.

In reality, to connect a

component to an existing line requires a T-connection . FluidSIM

automatically creates a T-connection when you draw a line from a

connection to an existing line.

In reality, to connect a

component to an existing line requires a T-connection . FluidSIM

automatically creates a T-connection when you draw a line from a

connection to an existing line.

Using the

cross-wires cursor

Using the

cross-wires cursor  draw a line between

the input connection of the pressure relief valve to the line

connecting the pump unit and the valve. Notice how the arrows in

the cross-wires turn inwards

draw a line between

the input connection of the pressure relief valve to the line

connecting the pump unit and the valve. Notice how the arrows in

the cross-wires turn inwards  .

.

Release the

mouse button.

Release the

mouse button.

The T-connection appears on the line at the point where the mouse button was released.

Connect the tank

to the pressure relief valve.

Connect the tank

to the pressure relief valve.

If necessary,

draw the line so that the wiring diagram is arranged

clearly.

If necessary,

draw the line so that the wiring diagram is arranged

clearly.

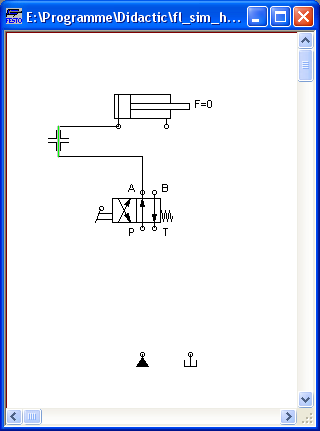

The circuit diagram should now appear somewhat like the following diagram:

Save the circuit

by clicking on

Save the circuit

by clicking on  or File- Save. FluidSIM automatically

opens the File Selector dialog box, if the title is new; here you

must give the circuit a name.

or File- Save. FluidSIM automatically

opens the File Selector dialog box, if the title is new; here you

must give the circuit a name.

Start the

simulation by clicking

Start the

simulation by clicking

.

.

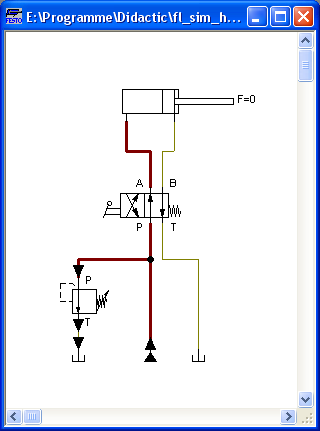

The cylinder's piston extends. As soon as the piston fully extends, a new situation arises. This situation is recognized by FluidSIM and is recalculated. The pressure relief valve opens and the distribution of pressure is shown:

FluidSIM not only animates

manually operated components during changeover, but nearly all

components with multiple states.

FluidSIM not only animates

manually operated components during changeover, but nearly all

components with multiple states.

The following figure shows a pressure relief valve in closed and open position:

Recall that in the Simulation Mode, manually operated valves and switches can be switched with a mouse click:

Move the mouse

cursor over the left-hand side of the valve.

Move the mouse

cursor over the left-hand side of the valve.

The mouse

cursor becomes a hand with an extended index finger

and indicates that the

valve can be switched.

and indicates that the

valve can be switched.

Click on the

left side of the valve and hold the mouse button down.

Click on the

left side of the valve and hold the mouse button down.

When you click on a valve, the real behavior of the valve is simulated. In our example the valve is switched to crossover position and a recalculation is initiated automatically. As a result, the pressure relief valve closes and the cylinder retracts. As soon as the cylinder reaches its left stop, the pressure relief valve opens again.

Components whose switching

status is not locked remain activated as long as the mouse button

is held down.

Components whose switching

status is not locked remain activated as long as the mouse button

is held down.

Stop the

simulation, which also brings you to Edit Mode. Select from the

component library the state diagram component, and place it onto

the drawing area.

Stop the

simulation, which also brings you to Edit Mode. Select from the

component library the state diagram component, and place it onto

the drawing area.

The state diagram records the state quantities of important components and depicts them graphically.

Move the state

diagram to a free place in the drawing. Drag the cylinder and

drop it onto the state diagram.

Move the state

diagram to a free place in the drawing. Drag the cylinder and

drop it onto the state diagram.

A dialog opens where you may choose the desired status variables. In this particular case only the position is of interest, so you may confirm the default selection by choosing OK.

Start the

simulation and observe the state diagram.

Start the

simulation and observe the state diagram.

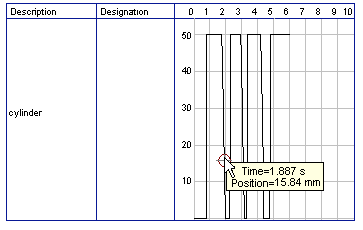

Set the

simulation to “Pause”-mode and move the mouse curser to the graph

in the diagram.

Set the

simulation to “Pause”-mode and move the mouse curser to the graph

in the diagram.

When resting on the diagram for approximately one second, the mouse curser will call a window indicating the exact values of time and of the applicable status variable. The display will move along and update the values when you move the mouse alongside the graph.

You may use several status diagrams in one window as well as you may display several components in the same diagram. By dragging a component onto the diagram you will add the component to the status diagram. A selection dialog will appear where you may choose the applicable status variables and different colors. A repeated drag onto the diagram will open the dialog again, so you may change your choice. In case no status variable of a component is selected, the component will be removed from the diagram. The following components and the applicable status variables may be displayed in the status variable diagram:

Recording state quantities in the state diagram

|

Component |

State |

|

cylinder |

position, velocity |

|

|

acceleration, force |

|

way valve |

position |

|

pressure meter, accumulator |

pressure |

|

shutoff valve and throttle valve |

opening level |

|

pump, motor |

rpm |

|

semi-rotary actuator |

position |

|

pressure valve and switching valves |

state, pressure |

|

flow control valves |

flow |

|

flow meter |

flow, volume |

|

pressure or switching valve |

state |

|

switch |

state |

|

relay, valve solenoid |

state |

|

indicator light, buzzer, pressure indicator |

state |

|

counter |

state, counter value |

|

function generator, voltmeter |

voltage |

|

status controller, PID-controller |

voltage |

The example is now finished. Further editing and simulation concepts are described in the next chapter.

Related Topic

Advanced Concepts in Simulating and Creating Circuits