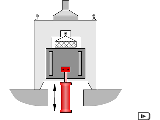

[168] Exercise: Paint drying oven (4/3-way valve)

Workpieces are fed

continuously through a paint drying oven on a conveyor belt. In

order to minimize the heat loss through the door, this should be

opened only as much as required by the height of the workpieces.

The hydraulic control system should be designed so that the door

can be held reliably in position for a long period of time

without slipping down. Firstly, a 4/3-way valve with suitable

mid-position functions should be selected as a final control

element. Secondly, a delockable non-return valve should be

provided in the circuit diagram to act as a hydraulic safety

device to prevent slippage of the door under load (i.e. its own

weight) over a long period of time as the result of leakage

losses in the directional control valve. The question is, which

type of 4/3-way valve has a suitable mid-position

function?

Workpieces are fed

continuously through a paint drying oven on a conveyor belt. In

order to minimize the heat loss through the door, this should be

opened only as much as required by the height of the workpieces.

The hydraulic control system should be designed so that the door

can be held reliably in position for a long period of time

without slipping down. Firstly, a 4/3-way valve with suitable

mid-position functions should be selected as a final control

element. Secondly, a delockable non-return valve should be

provided in the circuit diagram to act as a hydraulic safety

device to prevent slippage of the door under load (i.e. its own

weight) over a long period of time as the result of leakage

losses in the directional control valve. The question is, which

type of 4/3-way valve has a suitable mid-position

function?

A 4/3-way valve with an “all ports closed” mid-position will solve the problem only if a poppet valve is used. If a slide valve would be used, the oven door would slip down slowly as the result of internal leakage losses.

The second solution would be to fit a delockable non- return valve in the supply line to the piston rod side of the cylinder downstream of the directional control valve. In order to ensure that the non-return valve closes immediately when the door stops, both the outlets A and B of the directional control valve to the tank must be de-pressurized (A, B and T connected, P closed).