|

|

3.0 Introduction

Chapter Two described PhotoGrav’s operational

overview and how PhotoGrav uses these to provide a smooth flow of events

within a PhotoGrav

Session. This chapter, Chapter Three, provides a detailed description of each of

those primary functional blocks as well as describing a PhotoGrav Session

and the essentials of the PhotoGrav Application. The description with

appropriate graphics include: (1) PhotoGrav Sessions, (2) The Primary

Toolbar and its operations, (3) Viewing Panes and Panels, (4) Interactive Mode,

(5) Cloning—Comparison of Results, (6) Machine Selection, and (7) Automatic

Updates. It is especially recommended to become familiar with these primary

functional blocks located on the Primary Toolbar and the respective operations

since these are vital in producing a digital image for laser engraving.

3.1 PhotoGrav Sessions

One of PhotoGrav’s primary design concepts is the

notion of a “PhotoGrav Session” and its respective “Session File”

(*.pgs). A “Session File” is a file that is designed to save the current state

of ones work including all parameter settings, user preferences, machine and

material info, as well as the source image. By permitting the source

image to be saved with the session alleviates the need to remember where the

“original” image file is located. One can simply reopen the “Session File” and

perform any necessary modifications and/or adjustments without having to

relocate the original image. The machine information will be stored in the

“Session File” which is helpful, for example, if PhotoGrav is used with

multiple engravers. This permits one to save

machine/material “templates” such that the user can just open up the

session “template” pertaining to that particular machine/material and begin

using

PhotoGrav with the machine and material info already selected and

defined.

Whenever an image is opened, PhotoGrav will

automatically insert that image into either a new session OR an existing

active session. Either way there will always be only one image associated

with a PhotoGrav

Session.

Due to the “Session File” format, however, one must keep in

mind that there are two modes of selecting a machine and/or material.

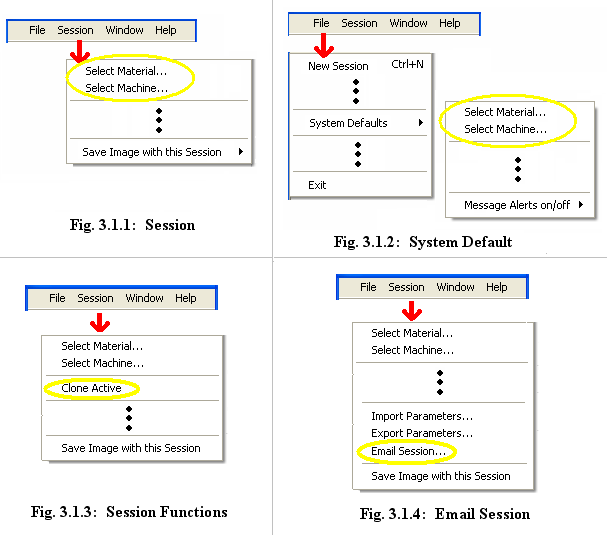

These two modes are selecting the “Session” machine/material (Figure 3.1.1) and

setting the “system” material/machine (Figure 3.1.2). The “Session” selection

stays with that particular session and the “System Default” selection sets the

default material/machine type so that any new session that is created will

default to the machine/material type that is selected in the “System Default”

settings.

Session files can be very useful when becoming proficient

with PhotoGrav in the following ways; when working with a difficult

image, if multiple engraving machines are used, when working with multiple

concurrent jobs, and in many other cases as well. PhotoGrav allows

multiple session files to be opened simultaneously and offers some functions

specifically related to Session files such as Cloning (Figure 3.1.3). For

further instruction on cloning refer to Section 3.5 on Cloning—Comparison of

Results .

PhotoGrav has the capability to email Session files

for easier review. For example PhotoGrav Session Files can be emailed to

PhotoGrav

Technical Support or to another office location for review simply by clicking on

the Session→Email Session… menu item (Fig 3.1.4).

From this point forward the majority of this section is in

the context of a “PhotoGrav Session” file (.pgs files).

3.2 Primary Toolbar

3.2.1 Overview

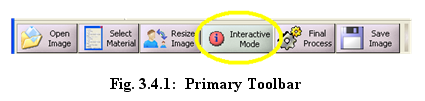

PhotoGrav is designed for simplicity, therefore, all

of the primary functions necessary to prepare an image for laser engraving are

grouped together and displayed in the “Primary Toolbar” (Fig 3.2.1). The Primary

Toolbar provides quick access to the most commonly used functions.

Fig. 3.2.1: Primary Toolbar

The Primary Toolbar has 5 basic functions that perform the

minimum requirement operations to successfully laser engrave an image or

photograph. As noted in Section 2.1 of this manual these 5 minimal steps are as

follows:

- Open an Image (Input Image).

- Select the engraving material.

- Resize the image to the desired size.

- Process the image.

- Save the image to disk.

3.2.2 Open Image

The Open Image button simply displays a dialog window that

allows an image in any PhotoGrav supported file type (bmp, jpg, tif, png)

to be opened and inserted into either a new or existing session window. While

the open file dialog filters the listed items to only show PhotoGrav

supported image types. If the “All files (*.*)” option is selected any

PhotoGrav file type can be opened such as PhotoGrav Session Files

(pgs), PhotoGrav Parameter Files (prm, pgp), or PhotoGrav

Supported Image Files (bmp, jpg, tif, png).

The image that is initially opened is considered the

“Original Image”. The image can be either color or grayscale. PhotoGrav

then automatically converts the original image if necessary to a “Grayscale

Image”.

PhotoGrav considers the grayscale image because it is often much more

reliable to compare the grayscale image (rather than the color image) to the

engraved image.

3.2.3 Select Material

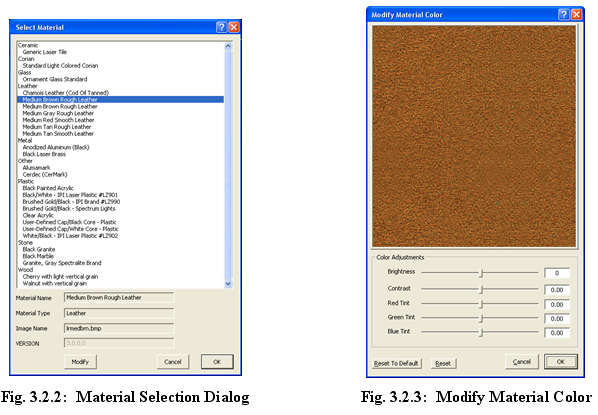

The “Select Material” button displays a dialog window listing

all the available materials sorted by the various categories (see Fig 3.2.2).

Remember that this material selection only changes the material for the “active”

session. Refer to Section 3.1, Fig 3.1.2 to see how to change the default

material setting. This list will be altered by the “Auto Update” feature (see

Section 3.7) as more materials become available for download. PhotoGrav

does not permit the user to modify this list due to the fact that many materials

individually and specifically tested and fine tuned for the best results. While

some material parameters are modifiable by the user there are a number of

parameters that are fixed during the design and testing phase of that material.

The material can also be chosen by double-clicking an item in the list or by

highlighting the material and clicking the “OK” button. The selected material

will then be displayed in the status bar at the bottom of the main application

window.

The Modify Material Color dialog window (Fig. 3.2.3)

can only be invoked from the Select Material dialog window and provides

the capability to the appearance of an engraving material. The capability to

modify the engraving material’s appearance enhances PhotoGrav’s

usefulness in two ways. The more important of the two ways is that it allows a

broad range of solid-color plastics to be effectively modeled by PhotoGrav.

This is achieved by providing two materials both of which have a User-Defined

Cap but one of which has a white core and the other has a black core. These

user-defined caps can be modified to have any solid color as will be described

below. The other way that the capability to modify the engraving material’s

appearance can be useful results from the fact that many engraving materials,

although similar to those provided by PhotoGrav, might differ somewhat in

color and brightness. The capability to alter their appearance might improve the

fidelity of the simulated engravings produced by PhotoGrav.

The material to be modified can be chosen by clicking a

material item in the list in Fig. 3.2.2 and then clicking the “Modify” button.

Pressing the “Modify” button causes the Modify Material dialog window to

appear.

The controls in the “Color Adjustments” frame are used to

modify the appearance of the engraving material. The “Brightness” and “Contrast”

controls affect the overall brightness and contrast of the material for all

colors equally. The “Brightness” modification can range from -100 to +100 and

the “Contrast” modification can range from -1.00 To + 1.00. The modification

values can be changed only by clicking the scrollbars, not by direct numerical

entries in the textboxes.

The “Red Tint”, “Green Tint”, and “Blue Tint” scrollbars

change the contrast of the respective colors. The tint modifications can range

from -1.00 to +1.00 and can be changed only by clicking the scrollbars, not by

direct numerical entries in the text boxes.

Modifications caused by the adjustments are immediately

visible in the material image view window. The “Reset” command button

resets all of the scroll bars to the “no adjustment” state since the last time

this material was modified. The “Reset to Default” button resets the

adjustments to the default setting of the material, in other words to the

settings of the material when originally shipped.

As an example try selecting the “User-Defined Cap/White Core”

material type under plastics. And click “Modify”. Then adjust the “Green Tint”

and “Blue Tint” slider bars so that both have a value of -1.00. Note that the

effect of these values is that the material image view window turns from white

to bright red. That red color could be further adjusted by changes in the

“Brightness”, “Contrast”, and “Red Tint” scroll bars. The net result is that one

can create almost any desired color for the cap of a solid-color plastic for

which the core color can be either white (in the example) or black.

3.2.4 Resize/Resample Image

Resizing and/or Resampling the original input image (Fig 3.2.4) is almost always

a requirement because one rarely receives the image in the actual size needed

for engraving (this does vary some depending on the engravers policies).

PhotoGrav offers the ability to resize/resample an image to the desired

size without having to depend on other outside methods. PhotoGrav will

raise a notification if it detects a discrepancy between the selected machine

resolution (dpi) and the resolution (dpi) of the image. The image should be

resampled to the same resolution (or an integer multiple of) as the desired

engraving resolution (machine dpi setting). PhotoGrav uses the machine

settings extensively to prepare and simulate the image to give the user an idea,

estimate, or relative difference of what to expect when the actual engraving is

performed. Therefore, PhotoGrav does not adjust the “actual engraver”

setting, which is usually modified through the software driver that comes with

the engraver, but rather only adjusts the “machine setting” in PhotoGrav

which is then used to prepare the image for engraving.

3.2.5 Final Process

The “Final Process” command button performs the actual

processing necessary to produce an image ready for the laser engraver. This

button should be pressed in every case prior to saving the image to disk. Once

the “Final Process” button is clicked PhotoGrav will process the image

using the current parameter settings. After the processing is complete

PhotoGrav will switch the image viewing pane to either the “Engraved” image

or the “Simulated” image determined by which image is selected in the viewing

pane toolbar (see Section 3.3, Fig 3.3.2). There will now be a total of three or

four images to use for comparison purposes in order to further fine tune the

results if needed.

3.2.6 Save Image

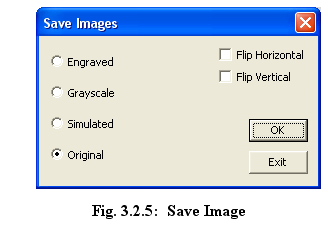

Now that the material has been selected and the image has

been opened, resized, and processed it is ready to be saved to disk for

engraving (Fig 3.2.5). To do this simply select the “Save Images” button on the

Primary Toolbar and save the appropriate images to disk in any of the

PhotoGrav

supported file formats. The only exception is the “Engraved” image which cannot

be saved as a jpeg due to the fact this format usually uses a lossy compression

type scheme which would create dire effects on the engraved image. One can elect

to save the images while flipping either horizontally, vertically or both. One

may find the “Flip Horizontal” check box to be turned on depending on the

material type selected due to the fact that some material types such as acrylic

engrave better on the back side, therefore requiring the image to be flipped or

mirrored. This can be altered, however, by modifying the parameters when in

Interactive Mode and then saving the session as a Template Session.

After the "Save Images" dialog is opened one

must select the “Exit” button to close out of this dialog screen. The reason for

this is that often it may be desirable to save more than just the “Engraved”

image so this goes into a continuous loop until all images are saved as needed.

3.2.7 Display Info

The remaining buttons on the Primary Toolbar have to do with

the way information is handled and viewed (see Fig 3.2.6). After pressing the

“Display Info” button the “PhotoGrav Session Report” window will be

displayed (Fig 1.6.1). This is a formatted report, that can be viewed or

printed, of the parameter, machine, and image settings for a particular session.

This report also includes thumbnail images of the original and simulated image

types. This provides an opportunity to print and file every job performed while

having quick access to all the data that was used for that job. One can also use

it to quickly view all the relevant settings for a session in a neatly organized

fashion. The PhotoGrav Session Report is also where an

estimate of the engraving time can be located and any comments that might be

helpful relating to the active session.

Fig. 3.2.6: Primary Toolbar

3.2.8 Size to Fit

The “Size to Fit” button zooms all the images to fit within

the viewing panes (see Section 3.3 for further information on Viewing Panes and

Panels).

3.2.9 Split Window

The “Split Window” button toggles between viewing the images

in a single or double viewing mode (see Section 3.3 for further information on

Viewing Panes and Panels).

3.3 Viewing Panes and Panels

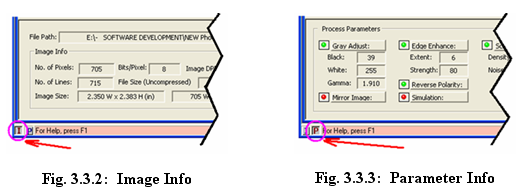

The second view that provides information is called the

“Panel” view. The “Panel” view is further divided into two subsequent views

named “Image Info” and “Parameter Info” (Fig 3.3.1). The “Image Info” panel (Fig

3.3.2) shows basic information about the image and the currently selected

machine. The next sub panel is the “Parameter Info” panel (Fig 3.3.3) which

displays a fixed summary of the current parameter settings. This “Parameter

Info” view changes to permit adjustments and modifications to the parameters

when in “Interactive Mode” which is discussed in Section 3.4.

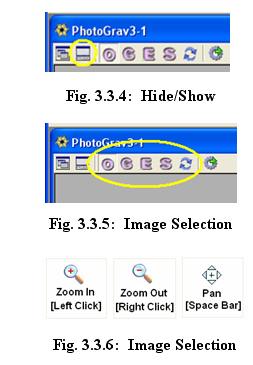

These panel views can be hidden to again provide for larger

viewing areas as needed by selecting the appropriate toolbar button from the

PhotoGrav Session Toolbar (Fig 3.3.4).

There are four images that one can select for viewing namely

Original input, Grayscale,

Engraved/binary, and the

Simulated images (Fig 3.3.5). If one has

“Split Screen” selected then these images can be selected independently per

image view. To open an image one can select the “Open Image” button on the

primary command bar. This button can be selected even if there is no session

window open in which case a new session window will be created and the

respective image inserted into that session. If, on the other hand, an existing

session is open then the selected image will be inserted over the existing image

if an image exists. In other words, if the user already has a session open then he

or she should create a “New” session prior to opening the image to prevent the

replacement of the existing session’s image.

By left or right clicking of the mouse button in either one

of the two Image View Windows one can incrementally zoom in or out respectively.

It is also possible to drag a zoom “box” or rectangle around the desired area

for closer inspection of the images. Another image command is the “pan” command.

This command centers the image at the point where the mouse button was clicked. Holding

down the [Space Bar] will activate this command (Fig 3.3.6).

3.4 Interactive Mode

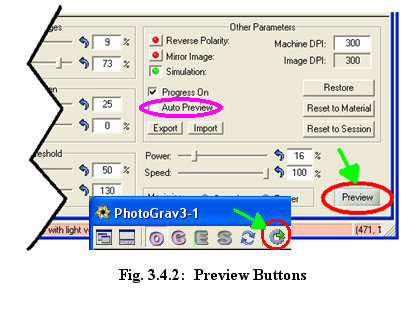

The Interactive Mode Button toggles between two modes

of operation. When in "Interactive Mode" the Interactive Mode Button will

show a green “i” icon indicating that PhotoGrav is in

"Interactive Mode". Similarly when

PhotoGrav is NOT in “Interactive Mode” the button will display a

red “i”.

The “Interactive Mode” is designed for the primary purpose of

providing a quick and efficient preview of the final image, since with average

size images it would simply take too long to run through the entire PhotoGrav

processing pipeline every time a small change is made to a parameter. With this

in mind PhotoGrav distinguishes between “Preview” and “Final Process”.

The “Final Process” button (formerly called “Auto Process” in previous versions)

takes the raw image data along with the current material, parameter, and machine

settings and completely processes the image producing the binary or engraved

image ready to be saved and engraved. On the other hand the “Preview” buttons

(only available in “Interactive Mode” - Fig 3.4.2) process a scaled version of

the image (NOT THE ORIGINAL IMAGE) suitable for rapid viewing as one adjusts and

modifies the parameters in almost if not real time.

PhotoGrav does not restrict the image view display

size therefore providing a larger viewing area for a more accurate

representation of the resulting image. A larger viewing area does require more

processing speed in order to maintain real time performance. The real time

performance of interactively adjusting the parameter settings is a direct

correlation to the size of the image and the size of the display screens viewing

area. Since

PhotoGrav permits arbitrary screen sizes it is better prepared to adapt

to the increasing speeds of modern computers. Assuming 17” to 24” computer

monitors and current average to high end computers one can expect almost real

time performance when interacting with the parameters while in “Interactive

Mode”.

Due to the plethora of monitor and display types,

resolutions, and sizes that exist in the market place today PhotoGrav

offers a couple of options to facilitate the advanced user who relies on the

“Interactive Mode” in their production cycle. The first option is the “Auto

Preview” checkbox (Fig 3.4.2). This is provided to give the user the ability to

regenerate the preview image automatically after each parameter adjustment

without the user having to manually click on the “Preview” buttons. The user may

select to turn this on or off depending on the image size and/or display screen

size to increase performance. The second option is the “Progress Bar On”

checkbox (Fig 3.4.2). This checkbox offers the user the option of increasing

performance by turning this off. When the progress bar is turned off

PhotoGrav will process the “Preview” image slightly faster, however, with

larger images and depending on the speed of the users’ computer one may want to

turn this on. By turning this on it gives a “heads up” as to what PhotoGrav

is doing followed by an indication when the “Preview” image is ready for

display.

Once the image and parameters are determined either in

“Interactive Mode” or otherwise then the user can select the “Final Process”

button to process the image. Clicking on the “Final Process” button inherently

assumes that the user is now ready to prepare and process the image for

engraving and exporting. Once the final processing is complete one can

export/save the images or compare the images to other sessions (see Section 3.5

on Cloning—Comparison of Results later on).

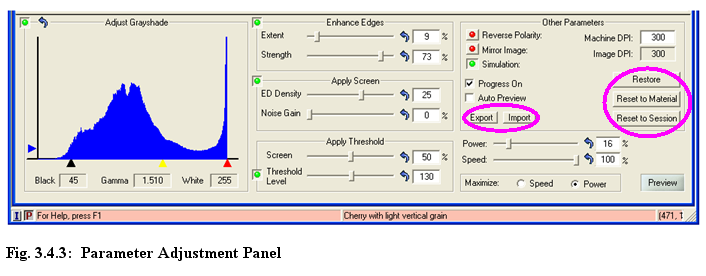

While working in “Interactive Mode” the user may want to

restore the parameters to a previous value. PhotoGrav provides parameter

restoration at 3 different levels (Fig 3.4.3). The first is “Restore” which

restores the parameter settings of the current session to the values it carried

along the last time that the image was processed using the “Final Process”

button. The second method of restoration is “Reset To System”. This resets the

parameters to the default settings of the base material selected for that

session. And finally the third level of restoring the parameters is “Reset To

Last Saved”. When one clicks this button it resets the parameters back to the

settings since the PhotoGrav Session was last saved.

It may be desirable to export or import (Fig 3.4.3) some

parameter settings while in Interactive Mode” and therefore PhotoGrav

offers these capabilities through the selection of the respective buttons.

PhotoGrav

allows the user to import parameter settings from version 2.xx (.prm files) or

version 3.xx and later (.pgp files), however, one can only export parameter

settings in version 3.xx and above “pgp” format. The parameters can also

be exported or imported via the menu bar at the top of the PhotoGrav

Application Window.

The remaining comments in this section describe the various

parameter settings and the respective controls. PhotoGrav has five major

processing functions whereby it transforms the original input image into the

Engraved and Simulated images. All processing function can be toggled on or off

by clicking on the small green or red lights beside each processing function

turning the functions on or off respectively. Furthermore, all processing

functions can be quickly reset by pressing the small blue “Reset” arrow beside

each control function.

3.4.1 Adjust Grayshade

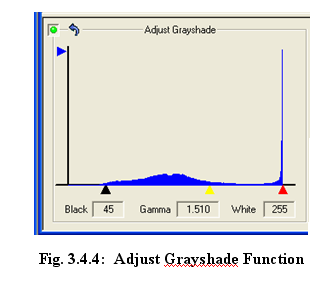

Figure 3.4.4 displays a histogram, or distribution, of the

gray shades in the Original (input) image. The horizontal axis ranges from zero

(black) on the left to 255 (white) on the right. The height of the distribution

indicates the relative number of image elements (pixels) that have the gray

shade indicated by the corresponding point on the horizontal axis. (If a

distribution is very “peaked” at certain gray shades, then the peaks are

truncated and other heights scaled to prevent the peaks from totally dominating

the distribution). As an example, for the distribution displayed in Fig. 3.4.4,

there are many more values of “white” in the image compared to any other gray

shade producing a large spike at the very far right of the histogram. The rest

of the histogram looks to have a higher concentration of values near the middle

of the gray shaded spectrum.

The left (black) and right (red) triangles below the

horizontal axis specify the black and white clipping values, respectively, for

the “Adjust Grayshade” function, i.e., all grayshades to the left of the left

triangle are set to black (zero) and all grayshades to the right of the right

triangle are set to white (255) and the grayshades between are linearly scaled.

The “Black” and “White” labels to the left of the distribution specify

quantitatively the black and white clipping values (45 and 255, respectively,

for the distribution in Fig. 3.4.4). The clipping values can be changed by

“clicking and dragging” the triangles. As a result, the “Black” and/or “White”

quantitative values will change and the effect will show up as a change in the

Processed and simulated Image. The clipping values can also, of course, be reset

by clicking the small blue “Reset” arrow. (Note: All the engraving

materials delivered with PhotoGrav calculate the “1%” clipping values for

the grayshade distribution).

The middle (yellow) triangle below the horizontal axis is the

“gamma” for the gray shade transfer function. Changing the gamma value, by

clicking and dragging the triangle, has the effect of simultaneously changing

the brightness and contrast of the image. Moving the triangle to the right will

generally make the Processed Image brighter and moving it to the left will

generally make it darker.

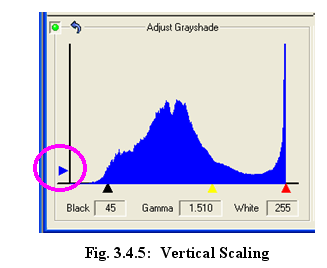

The blue triangle (Fig 3.4.5) that slides in the vertical

direction located on the left side of the histogram provides a scaling function

so that a few values do not dominate the graph. Note that in Figure 3.4.5 the

histogram shows a much more evenly distributed display thus far more readable.

Both Figure 3.4.4 and Figure 3.4.5 are the exact same histogram but note how the

two blue vertical triangles have different locations. By adjusting this vertical

scaling triangle a much more readable view of the image distribution is

achieved.

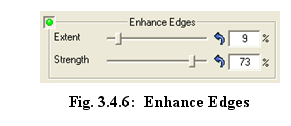

3.4.2 Enhance Edges

The “Enhance Edges” function provides the capability

to both “smooth” the image and to enhance the image’s edges. As with the “Adjust

Grayshade” function, if the green “On” button is checked, then the

function affects the image data; otherwise, if unchecked (red), there is NO

effect regardless of the parameter settings.

The “Extent” parameter pictured in Fig. 3.4.6 can be

modified by entering a value directly in the appropriate textbox (contains “9”

in Fig. 3.4.6) or by clicking the associated horizontal scrollbar. The "Extent"

parameter specifies the relative size of the area around each pixel which is

then smoothed. Small values indicate relatively little smoothing whereas large

values specify relatively large smoothing.

The “Strength” parameter specifies the degree to which

edges are enhanced or emphasized . The “Strength” parameter is controlled

in a manner similar to the “Extent” parameter except that its values

range from -100% to +100% rather than 0% to 100%. Almost all of the useful

settings for the “Strength” parameter are positive but interesting

effects can sometimes be achieved with negative settings.

Although PhotoGrav automatically sets parameter values

appropriate to each engraving material, it is a good idea for you to experiment

with the “Extent” and “Strength” parameter settings to get a feel

for their effect which at times can be rather dramatic. An interesting way to do

this is to have the “Simulation” ON and to turn the “Enhance Edges”

function alternately ON and OFF to observe the effect.

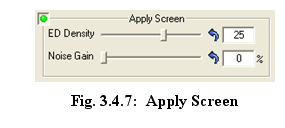

3.4.3 Apply Screen

The “Apply Screen” function (Fig. 3.4.7) provides the

capability to “screen” the image in preparation for thresholding which follows

this function.

The “Apply Screen” function actually performs a

Diffusion Dithering. Diffusion Dithering is a technique to convert a grayshade

image to a binary image (black & white only, no shades of gray) wherein the

shades of gray in the original image are represented in the processed binary

image by differing densities of black and/or white dots. Diffusion Dithering

accomplishes this by converting each gray shade in the original image to either

a black or white value depending on its value relative to a predetermined

“threshold” value. The error in making this assignment is then “diffused” to

neighboring pixels which eventually are also thresholded (and then error

diffused) and so forth and so on throughout the entire image.

The Diffusion Dithering within PhotoGrav has been

designed and optimized specifically for laser engraving and is controlled by the

two parameters indicated in Fig. 3.4.7: (1) ED Density and (2) Noise

Gain. (The ED stands for Error Diffusion). The “ED Density” parameter

can be used to darken lighter areas of the processed image without substantially

affecting areas that are already dark and, vice versa, can be used to lighten

darker areas of the image without substantially affecting areas that are already

light. The “Noise Gain” parameter can be used to add noise to the image

to reduce “contouring”, "repetitive pattern", or “jpeg artifacts” effects that

often occur when grayshade images are converted to binary images.

Both parameter values can be modified by clicking the scroll

bars or by entering numeric values in the white text boxes directly above each

scroll bar. Relative values for the “ED Density” parameter range from

-100 (darken) to +100 (lighten). Relative values for the “Noise Gain”

parameter range from 0% (no noise) to 100% (maximum noise).

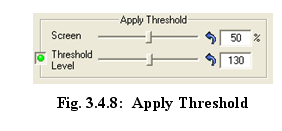

3.4.4 Apply Threshold

The “Apply Threshold” function (Fig 3.4.8) linearly

combines the last two control functions (Enhance and Screen), pixel by pixel and

with variable weights, before thresholding the result to create an

“Engraver-ready” binary image.

There are two parameters associated with the “Threshold”

function: (1) the “Screen %” and (2) the “Output Threshold Level”.

The first parameter, the “Screen %”, specifies how the two inputs to the

function are combined by specifying the weighting factor assigned to the input

from the “Screen” function. The weighting factor assigned to the image coming

from the “Enhance” function is then equal to (100 - Screen %) . A value of zero

for this parameter specifies that the resulting data, before thresholding, is

totally from the “Enhance” function. A value of “100” for this parameter

specifies that the data, before thresholding, is totally from the “Screen”

function. A value of “50” for this parameter specifies that the two inputs are

equally weighted and then combined. The “combine” portion of the “Threshold”

function is always ON, i.e., the two inputs are ALWAYS combined, before

thresholding, using the weighting factors specified by the “Screen %”

factor.

The second parameter, the “Threshold Level”, specifies

a threshold value which ranges from zero to 255. The threshold value is applied

to the combined output of the “Enhance” and “Screen” functions, weighted as

described above. If a combined value is less than the threshold value, then it

is assigned a zero (black). If a combined value is greater than the threshold

value, then it is assigned a one (white). The “threshold” portion of this

function, unlike the “combine” portion, can be turned ON or OFF by checking, or

not checking, the green/red checkbox located to the left of the label “Threshold

Level”. If the thresholding is OFF, then the simulation function, described in

the next section, cannot be turned ON and an engraver-ready (binary) image is

not produced.

Either parameter for this function can be modified by

clicking the horizontal scroll bars or by entering a numeric value in the white

text boxes immediately below the scroll bars.

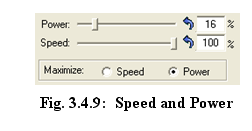

3.4.5 Speed and Power

The vertical scroll bars labeled “Power” and “Speed”

(Fig 3.4.9) specify the percentage of maximum power and the percentage of the

maximum speed for the laser engraver currently being modeled (You can change the

laser engraver being modeled as well as the specifications for any laser

engraver by selecting a different machine see Section 3.6). The “Power”

and “Speed” controls should be very similar to the controls which

actually exist on your laser engraver and should behave in the same fashion.

The “Maximize Power” and “Maximize Speed” (Fig

3.4.9) checkboxes determine whether the Power setting or Speed

setting for your machine is maximized when it is necessary to modify these

settings. The necessity for modifying these settings occurs since PhotoGrav’s

engraving materials were calibrated using a specific machine; therefore the

power, speed, resolution, etc. of your machine may not match those of

the “calibration” machine. PhotoGrav

strives to deliver the appropriate quantity of energy to each laser spot, based

on the settings for your machine, and in so doing has a choice of what values to

use for the Power and Speed settings (generally a large number of

settings will all satisfy the energy requirement). If you are interested in

engraving as fast as possible, then the “Maximize Speed” box should be

checked. If you are more comfortable with a higher Power setting, then

the “Maximize Power” box should be checked. These two boxes cannot both

be checked or unchecked at the same time so the boxes also act as toggles, i.e.,

if you check the “Maximize Power” box, then the “Maximize Speed”

box will automatically become unchecked and vice versa. (Note: The effect of

these checkboxes may at times appear confusing and it may at first appear to you

that they are not working properly. It is important to remember that “Maximize”

is used for both boxes to mean the maximum value for that parameter that will

still result in the proper energy being delivered to the laser spot

and that maximum value may not be 100%. For example, if the “Maximize Speed”

box is checked, then it would be possible for the Power and Speed

settings to be, e.g., 100% and 65%, respectively, which might at first seem

incorrect since “Speed” was to have been maximized. However, in the

example given, if the Speed is more than 65%, then inadequate energy will

be delivered to the laser spot since the Power setting cannot be more

than 100% (Speeding the engraver up delivers less energy to each spot). So, in

this case, 65% is indeed the “maximum” value for the Speed setting

subject to the constraint that the proper quantity of energy is delivered to the

laser spot).

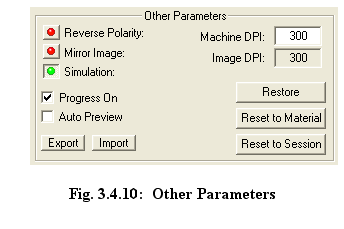

3.4.6 Other Parameters

The remaining parameter settings and various other functions

are located under the “Other Parameters” group box.

The text box labeled “Machine DPI”, containing the

value 300 in Fig 3.4.10, specifies the Engraver resolution, NOT the image

resolution, in dots per inch. The value in this textbox is initially taken from

the dpi value selected from the “Machine Preferences” dialog box. It

should be noted that when changing the “Machine DPI” will only cause the DPI

setting to become the Engraver resolution for the current session. The textbox

labeled “Image DPI” is for reference only and thus cannot be altered by

the user.

The “Reverse Polarity” checkbox provides the

capability to set the polarity of the Engraved and Simulation images. Positive

polarity materials are those for which the laser, when on, causes the engraving

material to become darker, e.g., most woods. Negative polarity materials are

those for which the laser, when on, causes the engraving material to become

lighter, e.g., black laser brass and acrylics. The “Mirror Image”

checkbox provides the capability to “mirror-the-image” (flip left to right) the

Engraved and Simulation images. This feature is useful for materials like

acrylic which are engraved on the “back” of the engraving material but viewed

from the front. For various reasons the processed image is not shown “mirrored”

in the Image Viewing Windows, but rather the Engraved and Simulated images are

flipped (by user selection) only when written to disk.

A few other options are also available such as turning the

Simulation on or off as well as exporting or importing parameters either from

the current or previous versions of PhotoGrav. Refer to the beginning of

this Section (3.4) for further information on most of these settings and

functions.

See Section 2.2 for a more complete discussion of the underlying

rationale for the simulation capability and how it can be an extraordinarily

useful tool.

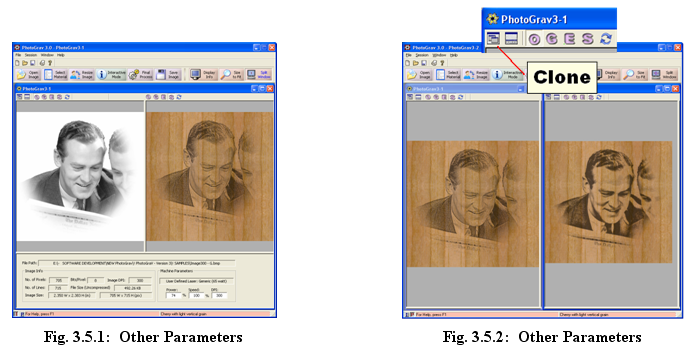

3.5 Cloning—Comparison of Results

The comparison of images whether simulated or otherwise can

be an efficient time saving procedure when it comes to preparing the image for

engraving. PhotoGrav offers two different methods by which one can

compare the processed image. The first is to compare the various images solely

within a particular session (Fig 3.5.1) and second is to compare the results of

two sessions with each other (Fig 3.5.2).

Learning how to use the “Cloning—Image Comparison” features

along with the simulation of results should again increase productivity. While

the simulation is attempting to get as close as possible to the final results

there are many variables that affect the results of the actual vs. the simulated

images. Therefore, the simulation can be thought of as a relative comparison of

the simulated images rather than an absolute final result. This essentially

means that once one learns how a particular “simulated” image compares to the

actual engraved image for a specific material and machine type; then a

“relative” difference or pattern should emerge giving the user a sense of how to

adjust the parameters to improve the actual engraving. This simulation feature

was significantly relied on during the design of PhotoGrav to improve

performance and efficiency.

PhotoGrav has a “Clone” function (Fig 3.5.2) to

further assist in comparing processed results. This “Clone” feature

assumes that the user wants to spin off or clone another session based on the

current active session. This provides an exact duplicate of the current selected

session or active session. This provides an efficient method to quickly process

another session and compare the two (if desired) without having to go through

the whole process of reopening the same image in another session. For example,

it can be helpful to compare one simulated or engraved image (session X), where

the parameters have been adjusted, with a second image (session Y) where the

parameters have NOT been modified (i.e. default material settings).

3.6 Machine Properties

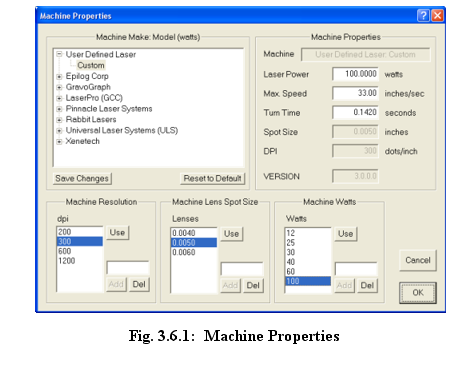

The “Machine Properties” dialog window (Fig. 3.6.1)

can only be invoked from the main application menu bar and is used to select and

modify the laser engraver and associated parameters which PhotoGrav is

currently modeling. The “Machine Make” frame provides the capability for you to

select your laser engraver manufacturer and model type. The “Machine

Properties”, “Machine Resolution”, “Machine Lens Spot Size”,

and “Machine Watts” frames provide the capability for you to modify, add

to, or specify completely, the parameters that essentially define the laser

engraver model.

The list at the top of the “Machine Model” frame displays the

laser engraver machines currently modeled by PhotoGrav including a “User

Defined Laser” machine for which you can completely specify the engraver

parameters from scratch. Each machine manufacturer in the list also provides a

“Generic” laser model type in the case where the specific model type is not known

but the manufacturer is known. In the case of the “Generic” model type all the

machine properties can be defined just as in the “User Defined Laser” case.

Selecting a machine from the list will enter the machine’s

name into the text box directly to the right of the list along with the machine

model type. It will also change all the settings to reflect which machine type

is selected.

Clicking the “Reset to Default” button will restore a

machine’s parameters, to the values they had when PhotoGrav was first

installed, for whatever machine is currently selected. Any machine’s parameters

can be modified using the controls in the “Machine Properties” dialog

window and, once the “OK” button is pressed, the modified parameters become the

current parameters for the machine and are stored to disk as such when the

current PhotoGrav session terminates).

The first two textboxes at the top of the “Machine

Properties” frame specify the maximum power (in watts) and the maximum speed

(in inches/second) for the current laser engraver. These two values obviously

have a big influence on how PhotoGrav produces the Simulated Image. The

third textbox from the top specifies the time, in seconds, for the laser to slow

down, stop, and reverse direction for each scan line. This parameter is used

only for calculating estimates of the engraving time, which are displayed in the

PhotoGrav Session Report (see Section 3.2.7). A procedure for calculating

this parameter for your particular machine is presented in Appendix 3:

Calculational Procedure for “Turn Time”.

PhotoGrav adjusts itself appropriately so that the simulated

engraving is as realistic as possible. The lens that is installed on the laser

engraver is the lens that should be specified in this textbox. Generally, for

photographs, the spot size corresponding to the highest-resolution is the best

lens to use, if that lens is available for your machine.

The second list is the “Machine Resolution” frame which

contains a list of the resolutions (dots per inch) available to the simulated

Laser Engraver. The controls in this frame behave identically to the controls in

the “Machine Lens Spot Size” frame as described in the paragraph above.

Similarly, the “Machine Watts” frame behaves just as the other two similar

frames.

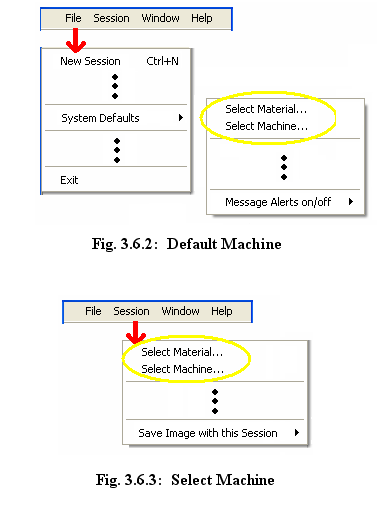

It is important to remember that there are two locations where

the “Machine Properties” can be selected. The first one is located under the

File→System Defaults→Select Machine… menu item (Fig 3.6.2). When this option

is selected ONLY THE DEFAULT MACHINE TYPE IS CHOSEN which means

that any new session that is created will use this machine type. The

second method of opening the “Machine Properties” dialog window is located in

the Session→Select Machine… menu item (Fig 3.6.3). When this method is

used ONLY THE ACTIVE SESSION MACHINE PROPERTIES ARE MODIFIED.

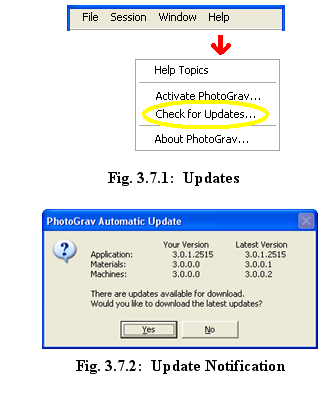

3.7 Automatic Updates

Another feature that can be very useful in PhotoGrav

is the ability for additional materials and machine types (when available) to be

added automatically via an internet connection on any computer that has

PhotoGrav

installed (Fig 3.7.1). This does not prevent one from still saving/exporting and

loading/importing parameter files and PhotoGrav Sessions (pgp

files) for both current and previous versions of PhotoGrav and

custom configuring the machine settings as required.

The available method to check for updates is through the Help

menu item as shown in Figure 3.7.1. There are three main items that

PhotoGrav

checks for when performing a “Check for Update” function. The first and second

are to check for any new Materials and Machines. The third is to check for any

updates to the application. If any one of these three checks indicates a need to

update then a message listing the current vs. latest versions available (Fig

3.7.2) appears. The updates can then be selected to “Yes” go ahead and download

or “No” just leave it as it is.