|

|

2.0 Introduction

The objective of this chapter is to present the essential information that you

need to know in order to effectively use PhotoGrav. Section 2.1 briefly

describes PhotoGrav's primary functions and flow of events that those functions

support during a typical PhotoGrav session. Beginning with PhotoGrav version 3.0

multiple simultaneous PhotoGrav sessions can be opened, modified, and

independently saved. Section 2.2 provides a concise, high-level description of

the program's concepts and the rationale for those concepts. Finally, section

2.3 presents a list of items that summarize the important information about

PhotoGrav.

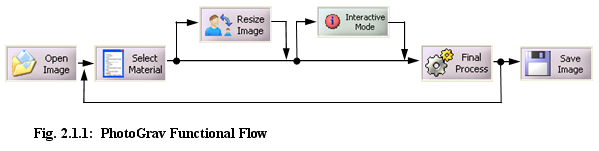

2.1 Functional Flow of Events

PhotoGrav employs a small number of primary toolbar buttons to functionally

organize the major steps involved in engraving a photograph. Each functional

button has one or more major functions to accomplish and, upon completion of

those functions, control passes back to the main session window. Figure 2.1.1

illustrates the normal flow of events in PhotoGrav processing.

The Open Image Button provides the capability to select the image that you want

to engrave while the Select Material Button selects the engraving material that

you want to use. PhotoGrav stores a set of processing parameters with each

material that it models. These processing parameters are optimized for each

particular material to ensure excellent engraving results without any user

intervention. These optimized parameters make possible the “Final Process” path

indicated in Fig 2.1-1.

The Resize Image Button provides the capability for you to resize/resample the

input image without having to rely on another software application to perform

this task. PhotoGrav will NOT resize or even modify the original image in any

way because PhotoGrav makes a working copy of the original file. Also, on every

resize/resample operation PhotoGrav uses the original image to perform the

resize operation in order to maintain the highest degree of quality.

The Interactive Mode Button provides the capability to individually specify

parameters for all of PhotoGrav’s processing functions and to view the result in

near real time. Most importantly, one can view a simulation of what the

engraving would actually look like on the material that you have selected.

Although the Interactive Mode provides complete access to PhotoGrav’s functions

that have been tuned specifically for Laser Engravers, you will probably find

that you can seldom do better than PhotoGrav’s Automatic Final Processing

option.

The Final Process Button (Auto Process in previous versions) allows the input

image to be processed and finalized in the proper format for the laser engraver.

To ensure that the image is processed and finalized with the latest

modifications of the parameters this operation should ALWAYS be performed

whether in Interactive Mode or otherwise prior to saving the image to disk.

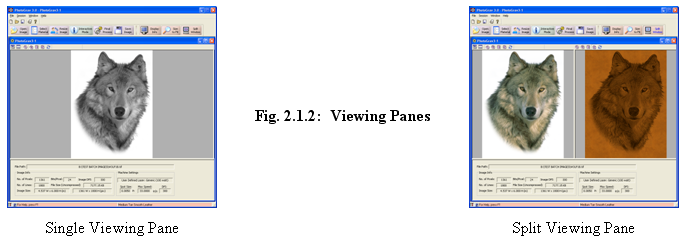

The Viewing Panes (Figure 2.1.2), whether in split mode or otherwise, displays

the Original (Input) image, the Grayscale image, the Engraved (Binary) image

(the image that is to be used for engraving), and the Simulated image (what the

engraving will look like on the selected material). The images appear on the

screen one or two (if in split mode) at a time. One can, however, click a button

to rapidly cycle through the various images for comparison purposes or view the

images side by side when in split view mode. You can also magnify the images by

clicking near the center of the area you want magnified or by defining a

rectangular area to be enlarged to fill the screen. All three images are

magnified by the same amount so comparisons are still easy to do even after

magnification. Once the processed image is acceptable the various images can be

save to disk for storing and to transfer to your engraver.

The Save Image Button allows the various images (Original, Grayscale, Engraved,

Simulated) to be saved to disk (when appropriate) in the supported file formats

i.e. jpg, tif, bmp, png. When saving the Engraved image the jpg file format is

NOT permitted due to the fact that in most cases it would ruin the engraved

image information which would not be suitable for engraving.

2.2 Basic PhotoGrav Concepts

The objective of the PhotoGrav program is to efficiently process digitized

photographs so they can be engraved on a variety of common engraving materials

with a high degree of confidence that the engraved photographs will be

acceptable products. This objective is achieved via two basic PhotoGrav

concepts:

1. Processing operations that are "tuned" for each engraving material, and

2. A simulation of the engraved image

The intent of this section of the user guide is to provide a concise, high-level

description of these two concepts and their underlying rationale. A more

detailed description can be found in "Appendix 5: PhotoGrav Concepts and

Design".

PhotoGrav's processing operations were designed and developed specifically to

process images for laser engraving and were parameterized so that a wide range

of effects could be achieved by adjustment of the parameters. Then the

parameters were individually "tuned" for each of the engraving materials

supported by the program. This "tuning" was accomplished experimentally, using

several test images, by specifying several sets of parameters for each engraving

material, actually engraving the images on the material, and evaluating the

resulting engravings. This process was repeated until the resultant engravings

appeared to be near optimal for the subject material. The parameters that

produced the final, "near optimal' engraving were then recorded and a data set

was created for the material. These data sets are stored as part of the

description of each engraving material and are automatically retrieved whenever

a material is selected as the current engraving material within PhotoGrav.

Although the tuning process described above results in "near optimal" parameter

settings for each engraving material, engraving results are still often somewhat

image dependent. In other words, the settings that produce an excellent

engraving for one image on a specific material might result in an engraving that

is less satisfactory for another image using the same engraving material.

Further, it is very difficult to view the raw processed image on a computer

monitor and to judge from that display whether or not the final engraving will

be satisfactory. To overcome these difficulties, PhotoGrav provides, optionally,

a simulation of what the processed image will look like once it is actually

engraved on the selected material and the ability to modify the parameters as

needed.

PhotoGrav's simulation capability is intended to provide a WYSIWYG (What You See

Is What You Get) capability. In other words, the appearance of the simulated

image on your computer monitor should be close to the appearance of the actual

engraving produced from the processed image for most of the included materials.

The simulated image is not merely an overlay of "dots" on top of a

representation of the engraving material, but rather a convolution of the

various parameters and images.

In other words, it is a full-fledged simulation wherein a lens-power model,

calibrated for each material, is used to calculate an effective laser spot size

which is then "burned" into a representation of the engraving material. Further

details about the simulation and model can be found in Appendix 5.

The Simulation Image produced by PhotoGrav should always be a representation of

the final engraving. For example, for "Black Laser Brass", the Simulation Image

should appear with proper polarity even though the processed image, if displayed

in its "raw" form, would appear to have a "negative" polarity. There is one

special case of this WYSIWYG capability that should be noted. For acrylics,

which are normally engraved on the "back" of the material, the Simulation Image

produced by PhotoGrav is the view from the "front" of the material, i.e., the normal viewing

perspective. So, even in this special case, the Simulation Image produced by

PhotoGrav is a true WYSIWYG representation, i.e., the simulated engraving is

presented as it would normally be viewed by your customers as a finished

product. Although the primary utility of the Simulation Image is to help you

make fine adjustments to create a more satisfactory engraving, it can also be

printed and used for customer proofs or as supplements to file copies of your

shop's projects. The prints are especially effective if you have a color printer

attached to your computer.

Although the simulation model has been calibrated for a variety of laser

engravers and for many common engraving materials, there are bound to be

variables that at times cause noticeable differences between PhotoGrav's

Simulation Image and the actual engraving. For example, black laser brass from

different manufacturers, or even different "batches" from the same manufacturer,

will sometimes engrave somewhat differently under identical engraver settings.

Also, variables in the laser engraver itself, e.g., dirty lenses or mirrors, can

cause variations in the engraving performance. You should try to control these

variables to the degree possible and also realize that PhotoGrav, like any other

tool, requires some practice and skill on your part to adapt its capabilities to

your particular environment and requirements. It is also important to remember

that, for engraved photographs, "beauty is in the eye of the beholder", i.e.,

the perceived goodness of an engraving is a very subjective measure. You might

therefore find that PhotoGrav's processing parameters for a particular material

do not result in engravings that match your tastes. If so, use PhotoGrav's

interactive processing capabilities (see Sec. 3.4) and its Named Parameter Sets

to define things the way you want them to be.

One other aspect of PhotoGrav's operational characteristics requires some

discussion before concluding this section. In the Image Viewing Panes (see Fig.

2.1.2), PhotoGrav displays the Original Image, the Grayscale Image, the Engraved

Image, and the Simulation Image for comparison purposes. The Grayscale Image is

the input image and the Engraved Image is the processed binary image that is to

be sent to the engraver. The Engraved Image is normally displayed in the same

polarity and the same left-to-right orientation as the Grayscale Image even

though those characteristics might be automatically changed by PhotoGrav when

the image is saved on disk for transfer to your engraver. The reason for

displaying the Engraved Image in this fashion is merely to facilitate the

comparison to the input image. If this is a bit confusing, just remember that

the Simulated Image always represents what will be engraved if you save the

processed image (Engraved Image in PhotoGrav's terminology) to disk and transfer

it to the engraver with no changes.

2.3 Important PhotoGrav Information

The following is a collection of important things that you should know about

PhotoGrav. Some of the items have already been discussed in previous sections

and some of them will be covered in later sections. However, since much of the

information following Chapter 2 is very detailed and is intended as reference

material, the essential elements of that information are summarized below so you

can begin using PhotoGrav with confidence after reading this section. If an item

is discussed elsewhere in this document, then a reference to the appropriate

section is included below.

- PhotoGrav has been designed for compatibility with a display screen color pixel

depth of 32-bit and a resolution of 1024 x 768 or larger. See section 1.2 of the

PhotoGrav User Guide for instructions on how to adjust this. (Reference: Sec.

3.3)

- The input image ("Original/Grayscale Image") for PhotoGrav can be any image type

in the following format: tif, bmp, jpg, png. (Reference: Sec. 3.2.2)

- The input image to PhotoGrav should be scanned in some image processing program

such as CorelDraw or Adobe PhotoShop, so that its size and resolution (dpi) are

"correct". If the image is already in a digital format then PhotoGrav is able to

resample the image to the desired size and resolution (dpi). Most images taken

with a digital camera have an arbitrary resolution of either 72 or 96 dpi. In

most engraving cases a dpi of 72 or 96 must be altered for best results.

The dpi (dots per inch) for the image should be the same, or an integer factor or divisor, of the dpi at which you intend to engrave the image. For example, if you intend to engrave at 250 or 500 dpi, then the image should be scanned at 250 dpi. If you intend to engrave at 300 or 600 dpi, then the image should be scanned at 300 dpi. Engraving results can often be very disappointing otherwise. The size of the image, at the scanned resolution (dpi), should be the desired size of the final engraved image.

- Processed photographs (PhotoGrav's "Engraved Image") should be engraved using

the highest resolution lens (smallest spot size) that you have available. If you

do not own your manufacturer's "high-resolution lens" and if you intend to

engrave a lot of photographs, then you might consider obtaining such a lens.

- Use PhotoGrav's “Machine Properties” or “Select Machine” dialog window to set

the parameters and characteristics for your specific laser engraver. The

“Machine Properties” window is accessible from the File→System Defaults→Select

Machine menu item. The session “Machine Properties” can be modified by selecting

Session→Select Machine from the menu bar. (Reference: Sec. 3.6)

Although you specified your Laser Engraver model and its maximum power on your very first PhotoGrav execution, there are other parameters that further define your specific machine. In particular, within the “Machine Properties” window, you should add and/or delete lenses from the “Lenses” list to match your set of lenses. Similarly, the list of “dpi's” should be edited to reflect the dpi settings available on your machine. Also, if your laser engraver’s maximum wattage is not listed under “Watts” then add it to the list as well.

- PhotoGrav is not designed to "Print" directly to laser engravers. To engrave a

PhotoGrav processed image (the "Engraved Image"), save the "Engraved Image" to

disk and use your standard program, e.g., CorelDraw, to send the image to the

engraver. (Reference: Sec. 4.1.2.1)

- DO NOT RESIZE NOR ROTATE the "Engraved Image" (the image to be sent to the

engraver) in CorelDraw, or any other image processing program, before sending it

to your engraver. The "Engraved Image" is a binary image, as it must be for

laser engraving, and resizing and rotation operations in general do not work

well for binary images.

- PhotoGrav's “Sessions” provide a powerful mechanism whereby you can customize

PhotoGrav's parameters to achieve the results you want and can be assured that

those results are repeatable in the future. If PhotoGrav's default parameter

settings do not provide a satisfactory result for a specific material after the

“Final Process” button is pressed, then select the “Interactive Mode” button to

create "Engraved Images" at several parameter settings that you suspect might be

better. Save the various “Session’s” with different names and then actually

engrave the images. Choose the engraving you prefer and then delete the

“Session’s” that do not correspond to that “best” engraving. If satisfied with

the “best” engraving, note which session was used and/or rename it so you can

readily access it in the future for similar engraving projects. Otherwise,

repeat the process until the results are satisfactory. You can now use this

“Session” as a template to begin other similar “Session” types. (Reference: Sec.

3.1)

- The engraving material to be modeled is selected via the “Material Properties”

dialog window. The “Material Properties” dialog window can be accessed by

selecting the File→System Defaults→Select Material menu item. The session

“Material Properties” can be modified by selecting Session→Select Material

from the menu bar. (Reference: Sec. 3.2.3)

- The leather materials included with PhotoGrav, unlike most of the other

furnished engraving materials, are not standardized materials. Further, the

engraving behavior of leather depends very much on the tanning process, whether

the leather is oiled or not, etc. therefore, PhotoGrav's Simulation Image for

any specific leather material might not be a good representation relative to the

specific leather material that you want to use. However, you can use the

furnished material as a starting point for your own calibration process wherein

you save your final, calibrated parameters as a PhotoGrav Session File

Template.

- The list of engraving materials includes two plastic materials that are

“User-Defined Caps” with white or black cores. These materials can be used

to model just about any plastic with a solid-color cap and with either a

black or white core. Some calibration and parameter adjustment, as described

in item 8 above, might be necessary for certain plastics and colors. (Reference: Sec. A1.1, Tip 5)

- Two copies of PhotoGrav cannot be running at the same time. If PhotoGrav

refuses to start, there is probably another copy of PhotoGrav running in a

minimized window.

- PhotoGrav produces temporary image files during its execution that can become

quite large if the input image is large. Try to maintain a reasonable quantity

of free disk space on the hard disk where you installed PhotoGrav (200 MB should

be more than adequate for most purposes).

- PhotoGrav is a Windows 32-bit program which runs equally well under 2000, XP, and Vista. A 64-bit version is planned to be released and it is recommended that you call PhotoGrav or check online at www.photograv.com for the latest information.